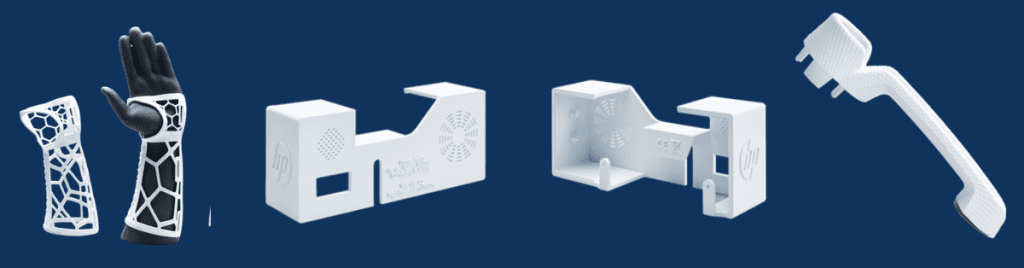

3D Printing Service, Additive Manufacturing, Service Bureau, Contract Manufacturing. Regardless of what nomenclature you prefer, Novastar Solutions can produce end-use parts from your CAD data.

We are currently providing Contract Manufacturing with our Farsoon 301M-2 in non-ferrous, Stainless 316. This dual-laser system welds powdered metal in 50-micron layers to 3D print parts in a process that is typically stronger and more fatigue resistant than a casting process, in a fraction of the time. Additive manufacturing also provides the opportunity to produce geometries or cavities that would be difficult or impossible with traditional manufacturing.

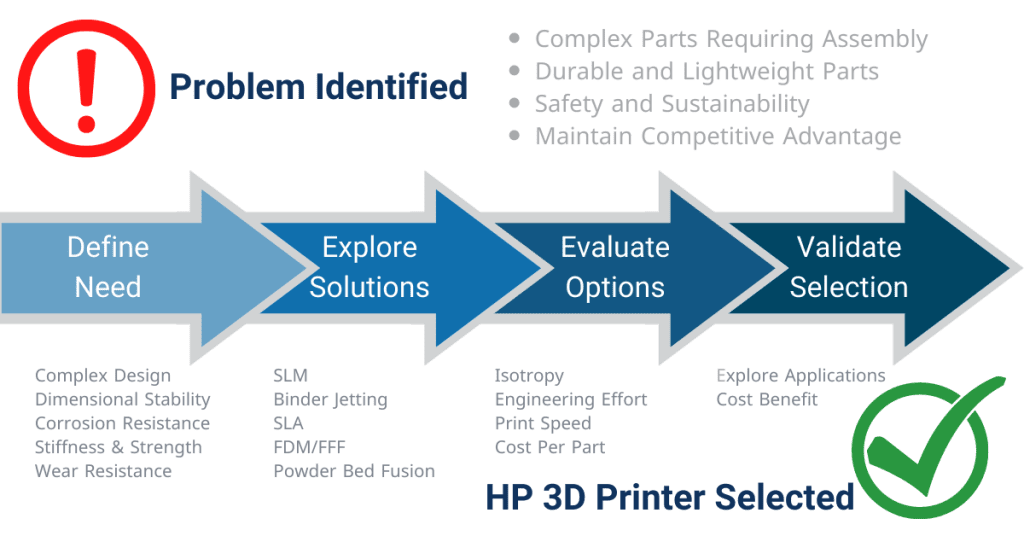

Our production process starts with a design review from our Additive Manufacturing Specialists and Application Engineer to ensure your files are optimized for the 3D printing process. We like to identify critical features, surfaces, and tolerances critical to the success of your designs. Once the design review has been completed, we can provide a quote for pricing and production timing.

If you would like to begin the review process, or simply make an inquiry please contact us at info@novastar.net to begin the conversation. We look forward to helping your prototype, pre-production, bridge manufacturing, or production process a success.